In a multicenter surgical survey, model size (100.00%), visual appearance (83.33%), and surgical anatomy (81.25%) were perceived as very realistic.

Results In mechanical tests, the model stiffness (E = 25.29 ± 2.68 kPa) was 5 orders of magnitude softer than common 3D printed materials, and less than an order of magnitude stiffer than mammalian brain tissue (E = 2.64 ± 0.40 kPa). The personalized brain model cost $50, and its fabrication took 24 hours.

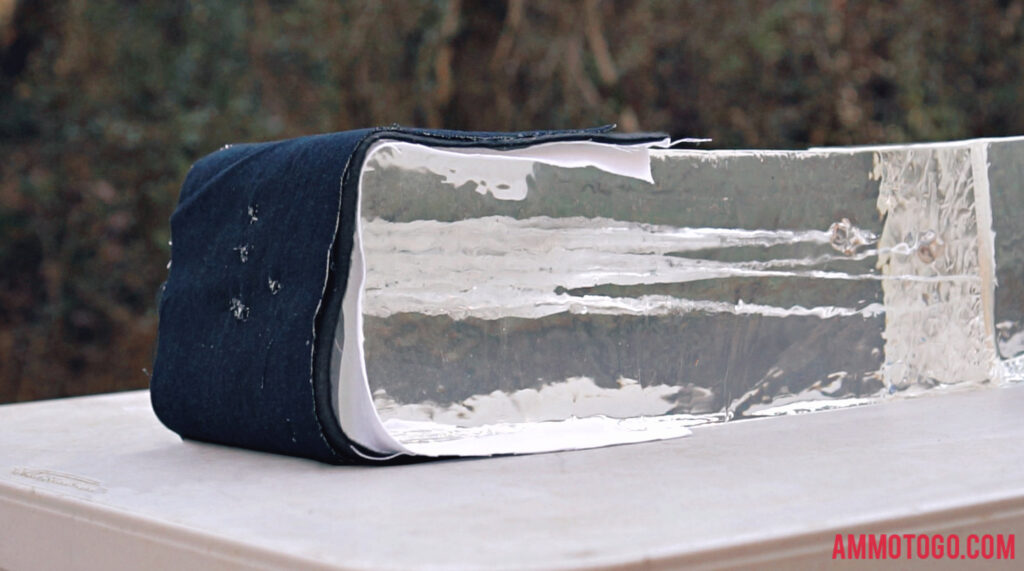

Created from soft gelatin, the model is easy to produce, cost-efficient, durable, and orders of magnitude softer than conventionally printed 3D models. Methods The method combines 3D printing, molding, and casting to create a physiologically, anatomically, and tactilely realistic model based on magnetic resonance images. Objective In this technical note, the authors present a new technology to create deformable, personalized models of the human brain. A major limitation is that current technologies are unable to directly print ultrasoft materials like human brain tissue. The growth of this cheap and easy additive manufacturing technology in orthopedic, plastic, and vascular surgery has been explosive however, its potential in the field of neurosurgery remains underexplored. Abstract: Background Three-dimensional (3D) printing holds promise for a wide variety of biomedical applications, from surgical planning, practicing, and teaching to creating implantable devices.

0 kommentar(er)

0 kommentar(er)